Enclosed Shot Blasting Robot and Surface Roughening Robot HighMate B Serie

Category:

Products

Keywords:

Shot Blasting Robot and Surface Roughening Robot HighMate B Serie

RobotPlusPlus

HighMate Series Product

HighMate Prepper

BeeBot

Sandblasting

shipyard robot

marine robot

HighMate B10 is specially designed for ship-building industries, using for grinding the weld seam for mega block assembly. It is 5 times more efficient than traditional manual way, with a perfect roughness of 50-90 μm. Using the robot allows the user to save cost from building scaffoldings and using construction basket, which also improves the safety of the operator to a large extent. The visual system let the user observe the cleaning process clearly, and the smart system makes it easy to operate in an automatic way.

HighMate B20 is another remarkable robot in the ship-building industries. It is used before the final paint is applied, to do a cleaning and roughening job on the ship hull, to make sure the paint stays long and well. The smart robot makes it possible for one operator to monitor two robots at the same time by using auto-navigation and lane-changing functions. B20 solves the problem of dangerous traditional manual work, and it is a perfect environmental-friendly solution for the maritime industry.

Product Features

B10: The weld seam shot blasting robot, independently developed by RobotPlusPlus, is primarily designed for shot blasting on the surfaces of steel plates. It efficiently achieves the required surface roughness, providing an optimal steel surface for subsequent painting processes. The robot is capable of adapting to curved surfaces with a curvature radius greater than 5 meters, ensuring stable and effective operation on the ship hull surface.

B20: RobotPlusPlus’s independently developed surface roughening robot is primarily used for the surface roughening of steel plates. It can adapt to curved surfaces with a curvature radius greater than 5 meters. The roughening process effectively removes dirt and surface dust, while also increasing the adhesion of new coatings. By equipping different cleaning modules, the robot can perform surface roughening operations on both flat and straight-bottomed sections of the ship hull.

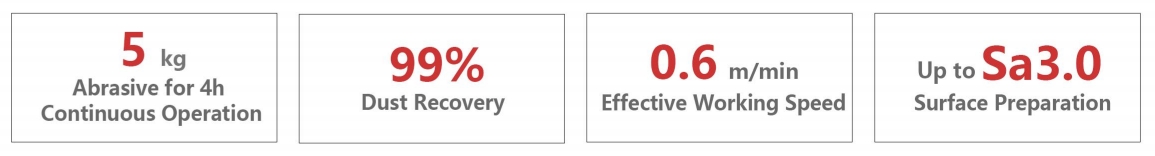

Technical Parameter

| HighMate B10 Specifications | |||

| Efficiency | 1.0m/min | Dimension | 905*500*500 mm |

| Weight | 72 kg | Working Width | 180 mm |

| Cleaning Result | Sa 2.5/Sa 3.0 | Protection Level | IP65 |

| Speed | 10 m/min | Abrasive | 1.0 mm Steel Grit |

| HighMate B20 Specifications | |||

| Efficiency | 150-180 m2/h | Dimension | 886*435*426 mm |

| Weight | 59 kg | Working Width | 400 mm |

| Driving Method | 400 W motor | Power supply | 220V AC |

| Speed | 10 m/min | Power | 3000 W |

Video

Online Message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

Recommended Products

Hydroblasting Robot HighMate V Serie

Hydroblasting Robot - HighMate V40 Ultra

HighMate AP Series Multi-Functional Robot

Swing Arm Multi Purpose Robot HighMate A Serie